ERP stands for Enterprise Resource Planning, a group of software programmes that help with production planning, supply chain management, raw material optimisation, and business process planning. Manufacturers use the production planning module of ERP software, i.e., the Manufacturing ERP Software to plan and oversee the entire manufacturing process, from product design to production and customer delivery.

ERP software offers remote access to all these operations, enhances inventory

management, and provides a real-time 360-degree perspective of the

organization.

Understanding Manufacturing ERP Software

Fundamentally, an ERP for manufacturing is an all-inclusive software programme

created to optimize and streamline the different parts of a manufacturing

process. It connects all departments and processes inside a manufacturing

organization, from production scheduling to inventory management, acting as

the company's central nervous system.

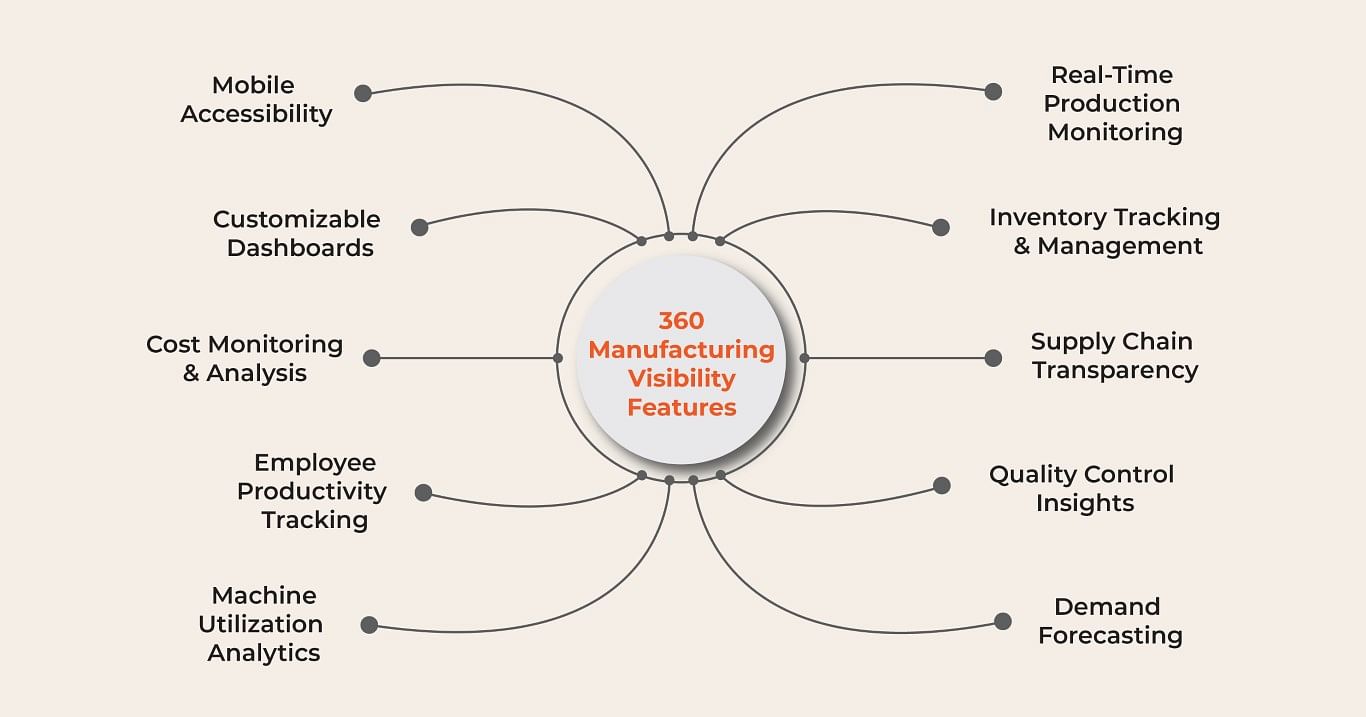

360 Manufacturing Visibility Features

✦ Real-Time Production Monitoring

ERP software offers real-time monitoring of industrial operations. It helps you

identify obstacles, track equipment efficiency, and make sure everything is

operating properly. It's like having a live video feed of your whole shop floor.

✦ Inventory Tracking & Management

Your inventory levels are tracked in real time via ERP's 360 Visibility feature. In

addition to warning you when supplies are running short, it also assists in

optimizing inventory levels to avoid problems with overstocking or understocking.

✦ Supply Chain Transparency

Supply Chain Visibility from ERP guarantees transparency at every level, assisting

you in making wise decisions and establishing solid relationships with your

suppliers.

✦ Quality Control Insights

Manufacturing ERP’s Visibility feature tracks quality control checkpoints

throughout the production process. It's like having a quality control superhero

ensuring that only top-notch products leave your facility.

✦ Demand Forecasting

You may forecast future demand with ERP's 360 Visibility by using past data,

industry trends, and consumer behavior. You can efficiently manage resources,

set production schedules, and keep one step ahead of market demands with the

aid of this forecasting superpower.

✦ Machine Utilization Analytics

Machines are the backbone of manufacturing, and knowing how efficiently

they're working is crucial. ERP's 360 Visibility feature provides insights into

machine utilization – which machines are running at full capacity, which ones

need maintenance, and how you can optimize their performance.

✦ Employee Productivity Tracking

ERP's 360 Visibility extends to tracking employee productivity. It helps you

optimize work schedules, provide necessary training, and create a more efficient

workforce.

✦ Cost Monitoring & Analysis

Keeping a close eye on costs is a constant battle. ERP's 360 Visibility allows you to

monitor production costs in real time. It breaks down costs at every stage, helping

you identify areas for cost reduction, optimize spending, and improve overall

profitability.

✦ Customizable Dashboards

ERP's 360 Visibility feature understands this and offers customizable dashboards.

It's like having a control panel where you decide what information is most crucial

for your daily operations, ensuring you see what matters most to you.

✦ Mobile Accessibility

ERP's 360 Visibility is mobile-friendly, allowing you to access critical data from

your smartphone or tablet. It's like having a portable window into your

manufacturing world.

Explore more about our Manufacturing ERP Software

Get in Touch

The Impact on Manufacturing Efficiency

✥ Streamlined Production Processes

With real-time monitoring, you can

identify inefficiencies and bottlenecks instantly. This means smoother

production processes, reduced downtime, and faster delivery of products

to customers.

✥ Improved Decision-Making

When you can see every aspect of your

manufacturing process, decisions become more informed. From adjusting

production schedules to optimizing inventory levels, you make decisions

that positively impact your bottom line.

✥ Enhanced Quality Control

Spotting quality issues in real time ensures that

only top-quality products reach your customers. This not only boosts

customer satisfaction but also saves costs associated with returns and

rework.

✥ Cost Savings

Understanding where your money is going and optimizing

costs at every stage leads to significant savings. Whether it's reducing

machine downtime, optimizing employee schedules, or minimizing

inventory holding costs, ERP's 360 Visibility is a cost-saving wizard.

✥ Adaptability to Market Changes

The ability to forecast demand and track

market trends means you're always one step ahead. You can adjust

production schedules, introduce new products, or shift focus based on

real-time market dynamics.

Choosing the Right Manufacturing ERP Software

Scalability

Your business is unique, and it's bound to grow. Choose ERP software that can

scale with your business, accommodating increased data, users, and processes

without a hitch.

Integration Capabilities

Your ERP should be like a conductor orchestrating a symphony. It should

seamlessly integrate with your existing systems, whether it's your CRM,

accounting software, or e-commerce platform.

User-Friendly Interface

Look for ERP software with an intuitive and user-friendly interface, ensuring that

everyone in your organization can leverage its power.

Cloud-Based vs On-Premises

Consider whether a cloud-based or on-premises ERP solution suits your business.

Cloud-based options offer flexibility and accessibility, while on-premises solutions

provide more control over data.

Vendors Support

Choose a vendor that provides excellent customer support to ensure that you

have assistance when needed.

Data Security

Ensuring that manufacturing ERP prioritizes sensitive data security. Features like user access controls, data encryption, and regular security updates can help.

Conclusion

Investing in the right Manufacturing ERP Software is not just about embracing

technology; it's about future-proofing your business. It's about stepping into a

world where you have the power to see, predict, and optimize every aspect of your

manufacturing process.

About Silent Infotech

Silent Infotech isn't just another ERP company. We're your manufacturing companion, empowering you with the most advanced software to simplify and revolutionize your operations. We seamlessly integrate production planning, inventory management, and more into one custom-built solution, giving you real-time visibility and control from raw materials to finished products.

Tushar C

A seasoned tech enthusiast, holds the position of CEO at Silent Infotech and serves as the CTO at SpeedBot, an algorithmic trading platform. Renowned internationally as a speaker on emerging technologies, Tushar boasts over a decade of diverse experience in the tech industry. His journey commenced as a developer in a multinational corporation, and he later co-founded Silent Infotech alongside two other members. Tushar's expertise spans a multitude of technologies, including blockchain, AI, Python, Dotnet, and cloud solutions. He leverages his extensive knowledge to deliver a broad spectrum of enterprise solutions to businesses. A true technology master, Tushar excels in managing cloud infrastructure for large-scale enterprises. To learn more about his insights and expertise, connect with him.

Schedule Consultation with Tushar Schedule Now