Industry 4.0 is transforming manufacturing. Over a trillion dollars (USD) have been invested in digitally transforming six major industrial sectors. With this digital revolution, manufacturers can improve operational efficiency, cut costs, and enhance customer experience.

In Industry 4.0, sensors and automation monitor and control production and data analysis to optimize operations and product quality. Manufacturers must adopt this cutting-edge technology to compete in the ever-changing business climate. Data is the new currency. Thus, using it for innovation and operation improvement is crucial.

Digital technology help manufacturers satisfy client expectations and adapt to market developments. Industry 4.0’s digital transformation in manufacturing helps solve climate change. These technologies enable manufacturers to reduce their carbon footprint.

It supports a sustainable future by creating eco-friendly and sustainable production processes. This article discusses the benefits, problems, and opportunities of Digital Transformation.

Digital Transformation on Manufacturing: An Overview

Digital Transformation has helped the industrial industry survive. By 2026, it is expected that the world will have spent $3.4 trillion on digital change. Using this intelligent, tech-based strategy, companies can use industrial solutions to quickly adjust the display to changing conditions, streamline processes, optimize output, and improve management and internal workflows.

Digital Transformation in Manufacturing involves using digital solutions to replace non-digital production and related operations. Manufacturing generates much data from social media, CRM and ERP systems, and transactions from its IT infrastructure, supply chain, manufacturing floor, and back office. Digital solutions combine assets and data to bring value to every process and operation.

Industry 4.0 is the current industrial revolution that automates operations and enables real-time control by integrating assets and data and blending digital and traditional factories.

The Effects of the Digital Revolution on the Manufacturing Sector

Digital Transformation in Manufacturing improves safety, quality, throughput, efficiency, revenue, sustainability, and competitiveness by lowering costs. To meet changing client expectations and fierce competition, this shift is huge. Digitalizing manufacturing enterprises have several primary benefits:

- Digital safety solutions reduce workplace injuries and accidents.

- Improved output quality reduces product rework, warranty work, and customer pleasure.

- Process efficiency boosts productivity and profits.

- Your firm, shareholders, and customers benefit from a solid bottom line while you innovate and sustain your market.

Digital Transformation has produced real-time industrial data. These digital procedures capture data instantly, enabling real-time business choices. Predictive analytics and reactive reactions are used. This normalizes preventative maintenance and failure techniques that impact the entire enterprise.

Digital Transformation in Manufacturing empowers people to improve processes, hold themselves and others accountable, and have a continuous improvement mindset in the company. Empowerment is most effective when matched with the company’s mission and conveyed to employees.

Manufacturing Digital Transformation Success Factors

Industry 4.0 and digital technology have transformed manufacturing in recent years. Digital Transformation in Manufacturing needs the right technology, a supportive environment, and data and analytics.

Industry 4.0 Technology and Processes Implementation

Industry 4.0 incorporates modern technology like the Internet of Things (IoT), artificial intelligence (AI), and robotics into manufacturing. These technologies are essential to manufacturing’s digital transition. Manufacturers can use these technologies to cut costs, increase productivity, and improve product quality.

Data Analytics Infrastructure Investment

Nearly 50% of those surveyed saw cloud computing as a promising area for future investment in data and analytics technology. Data drives manufacturing Digital Transformation. Manufacturers seeking Industry 4.0 potential must invest in data and analytics infrastructure. This infrastructure should gather, store, and analyze data from IoT devices, equipment, and manufacturing lines. This data can help producers make smarter decisions, enhance procedures, and outperform the competition.

Establishing A Digital-First Mindset

A digital-first culture and mindset are necessary for manufacturing’s digital revolution. This means manufacturers must embrace digital technologies and focus on customers. Companies must equip their staff with the essential tools, training, and support to harness new technologies and foster a culture of innovation and continuous improvement.

Connected And Smart Automation

Smart automation and networked systems are essential to digital production. Manufacturers can improve productivity and reduce errors by automating repetitive procedures and integrating systems and devices. These connected systems can also provide insights into production processes, helping firms enhance and optimize operations.

Challenges Hindering Digital Transformation Initiatives in Manufacturing Companies

Advanced digital solutions benefit manufacturing companies. It cuts expenses, boosts ROI, and improves customer service. Despite these benefits, Digital Transformation programs face hurdles. Some challenges:

The consent of upper management

The approval of higher management is required because going digital will result in considerable financial outlays and major changes to workflow and HR management. Therefore, acquiring permission from the higher-ups in the company might be challenging.

The Realignment of the IT Department

It is essential to fine-tune all IT-related activities and the organization of the IT department and the technology stack to undertake Digital Transformation successfully.

Personnel support

Altering workflows, timetables, responsibilities, and staff schedules, as well as providing additional training, may be met with resistance from personnel. As a result, businesses need to ensure that they have the support of their workforce to undergo Digital Transformation successfully.

Budget Limitations

Incorporating new manufacturing technologies typically demands significant financial investments, challenging various companies.

Extremely Connected Manufacturing Systems

Alterations and transformations could not be an option in situations with a close connection between the components and where even a short delay could have catastrophic results.

Changing Customer Behaviors

The ever-evolving expectations of consumers encourage businesses to speculate about their customers’ future requirements. As a result, preventative actions involving Digital Transformation are required.

Supercharge your manufacturing business with Industry 4.0 digital transformation! Elevate your ERP system with the power of IoT, AI analytics, and interactive dashboards. Unleash new efficiencies, insights, and growth opportunities. Upgrade your business today!

Digital Transformation Strategy For Manufacturing

A

Step 1: Determine Objectives and Evaluate the Current Situation.

The first stage in creating a Digital Transformation roadmap is to examine the company’s current situation and set clear, quantifiable goals. This should involve analyzing the company’s technology, data infrastructure, operations, and culture. Goals should correspond with the company’s business plan and address short-term and long-term demands.

Step 2: Make a List Of Priorities and Draw Up a Strategy.

Identifying transformation priorities follows defining the present condition and goals. This should be done with critical stakeholders considering resources, timeframe, and business impact. A detailed transformation plan should be created based on priorities. This strategy should include tasks, timelines, resources, and stakeholder roles and responsibilities.

Step 3: Put it Into Action and Track Your Results

The Digital Transformation plan is executed during implementation. As personnel and processes adjust to new technology and methods, this will require a lot of change management. Communicating the transformation’s benefits clearly and providing support and training is crucial.

Finally, progress should be routinely assessed, and the roadmap should be changed as needed. This will help maintain the transition and meet goals.

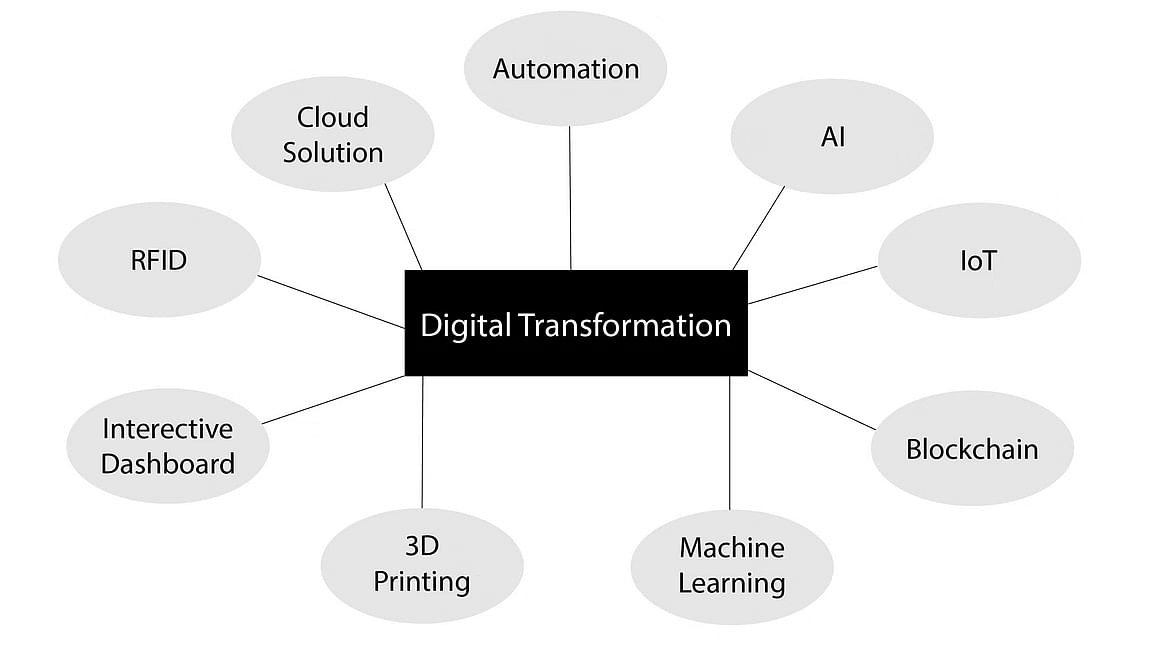

Critical Technologies of Digital Transformation In Manufacturing

Learn more about the technologies driving the most significant developments and advances in the industry with us.

The Internet of Things (IOT)

In manufacturing, the Industrial Internet of Things (IIoT) is used in practically all innovations. Industrial Internet of Things (IIoT) platforms for manufacturing industries are estimated to reach 22.3 billion U.S. dollars by 2025. With IoT-based solutions, companies can monitor the manufacturing floor, improve performance, and handle issues in real-time. These solutions enhance production, people, and asset management. Improve overall production procedures.

IoT solutions enhance manufacturing operations, save energy and resources, eliminate errors, increase product quality, limit downtime, and manage staff. IoT systems let firms monitor and improve staff productivity and create a happy workplace—through asset management. IoT solutions can track inventory, performance, and maintenance by seeing all linked devices.

3D Printing

3D printing has helped numerous industries speed up manufacturing despite its youth. How? This additive technology makes prototypes and parts faster than shipping. It’s fast and cheap. A manufacturer designs and a 3D printer prints it in resin, plastic, or other materials. The technology reduces manufacturing costs and time to market.

Artificial Intelligence

AI’s advantages over pre-programmed systems have transformed production. AI solutions examine data, learn patterns, and offer important insights. AI’s ability to observe and think like humans make it crucial in industrial jobs, including decision-making, product and feature configuration, quality control and issue identification, predictive maintenance, and predictive analytics.

59% of manufacturers say quality control is the essential AI use case. AI-based tools help manufacturers cut costs, boost efficiency, and improve customer service. AI can detect and fix real-time issues, reducing downtime and improving equipment efficiency.

Manufacturers may stay competitive in a fast-changing business climate by using AI-based technologies to make data-driven decisions.

Machine Learning

Intelligent algorithms replicate human learning power, machine learning solutions, and many efficient technologies that help firms enhance operations. By 2030, the market for machine learning is projected to expand from its current level of about USD 140 billion to USD approximately USD 2 trillion.

By balancing quality and effectiveness, clever algorithms change how organizations collect data and make predictions.

Machine learning solutions eliminate waste and errors and improve accuracy and precision due to their greater efficiency than people. Customer demand, shipment schedules, delays, risk prevention models, and more can be predicted using machine learning algorithms.

Blockchain

This technology was made for Bitcoin, but many other fields, including the manufacturing business, have quickly adopted it. In manufacturing, it helps make smart supply lines that track every moment and part of a product’s lifecycle. Because of this, businesses are safe from fraud, theft, cyber-attacks, and other things. The IoT system doesn’t have to use the central cloud service to handle devices when working with IoT.

Digital Transformation In Manufacturing: Future

Emerging Technologies and Trends

AI and ML are defining the future of Digital Transformation in the industry. These technologies can help manufacturers optimize decision-making, use data better, and automate repetitive jobs. The rise of the Internet of Things (IoT) in manufacturing is another trend.

The IoT is a network of connected devices that can interact and share data, which could improve manufacturing operations.

A Strategy For Change and Transformation

Transitioning from conventional production is expensive, complicated, and time-consuming but worth it. A cautious approach helps a corporation run smoothly. Let’s discover an excellent strategy’s fundamentals.

Optimization of Operations and Processes

Companies should evaluate their IT capabilities, perform a cost-benefit analysis, and find opportunities for improvement in production, HR, product quality assurance, etc. Here, LEAN manufacturing helps identify critical areas and develop a transformation strategy.

Process optimization and engineering, operational, and information technology will stimulate new, more efficient working models and enhancement roadmaps.

AI and Internet of Things Implementation

These technologies help enhance productivity, which in turn helps raise revenues and reduce waste, making them incredibly efficient in their application in the industrial business.

For businesses to take advantage of these benefits, they should prioritize implementing these technologies and their seamless integration with engineering and operational systems.

Using Data Obtained From Customers

By collecting and processing customer information, modern direct-to-customer business models enable manufacturers to better understand their customers and their requirements. Manufacturing businesses can become closer to their end consumers and better meet their wants and, as a result, demands if they design a system that can store and alter customer information. This allows the companies to get closer to their end customers.

Approaching Things in an Unusual Way

Some firms try unconventional strategies to win the loyalty of their clients. One such manufacturer is John Deere, which produces tractors and has created an online store where they sell a variety of things that complement and relate to their main line of business.

This forward-thinking strategy enables the company to generate revenue and collect information about its customers unorthodoxly, putting it in a commanding position relative to its rivals.

Training of Personnel & Retraining of Skilled Workers

Because complex devices and sophisticated platforms require entirely new skills and expertise, businesses should invest in training their existing staff or hire new team members to keep up with industry demands. This indicates that individuals should prepare for significant time and financial investment.

Final Thoughts

In conclusion, Digital Transformation has dramatically affected manufacturing. It has revolutionized production with new tools and technology. Robotics, automation, the Internet of Things, and big data analytics have enhanced efficiency, productivity, and cost-effectiveness.

Digital Transformation‘s individualized products and services have also improved client satisfaction. It has also introduced innovative business concepts like product-as-a-service. Technological innovations necessitate new worker abilities.

Manufacturers must train workers to operate and maintain these new technologies. Digital Transformation has had a tremendous impact on production, and as technology advances, manufacturers must adapt to stay competitive.

| About Author

Rajesh R

A seasoned IT Integrations and ERP Solution Architect boasts over a decade's expertise in revolutionizing business processes through cloud-based ERP and MIS software solutions. Proficient in leveraging avant-garde technologies such as Blockchain, Al, IoT, etc in crafting bespoke software solutions. His extensive background encompasses tailor-made software solutions across diverse industries like Sales, Manufacturing, Food Processing, Warehouse Operations→ and B2B Businesses. Rajesh excels in engineering and deploying enterprise-grade business software, playing a pivotal role in Business Solution Consulting and designing intricate software solution architectures for many Fortune 500 enterprises.

Schedule Consultation with Rajesh Schedule Now