Unlock Inventory Efficiency With Barcode-Based Warehouse Management System

Managing inventory efficiently is one of the biggest challenges for businesses of all sizes. The traditional inventory management methods involving manual data entry and paperwork can be time-consuming, error-prone, and inefficient. However, with technological advancements, businesses can now rely on a competent barcode warehouse management system (WMS) to streamline their inventory management processes. Barcode-based WMS systems offer several benefits, including accurate inventory tracking, increased efficiency, improved customer satisfaction, and cost savings.

What Is Barcode-Based Inventory Management?

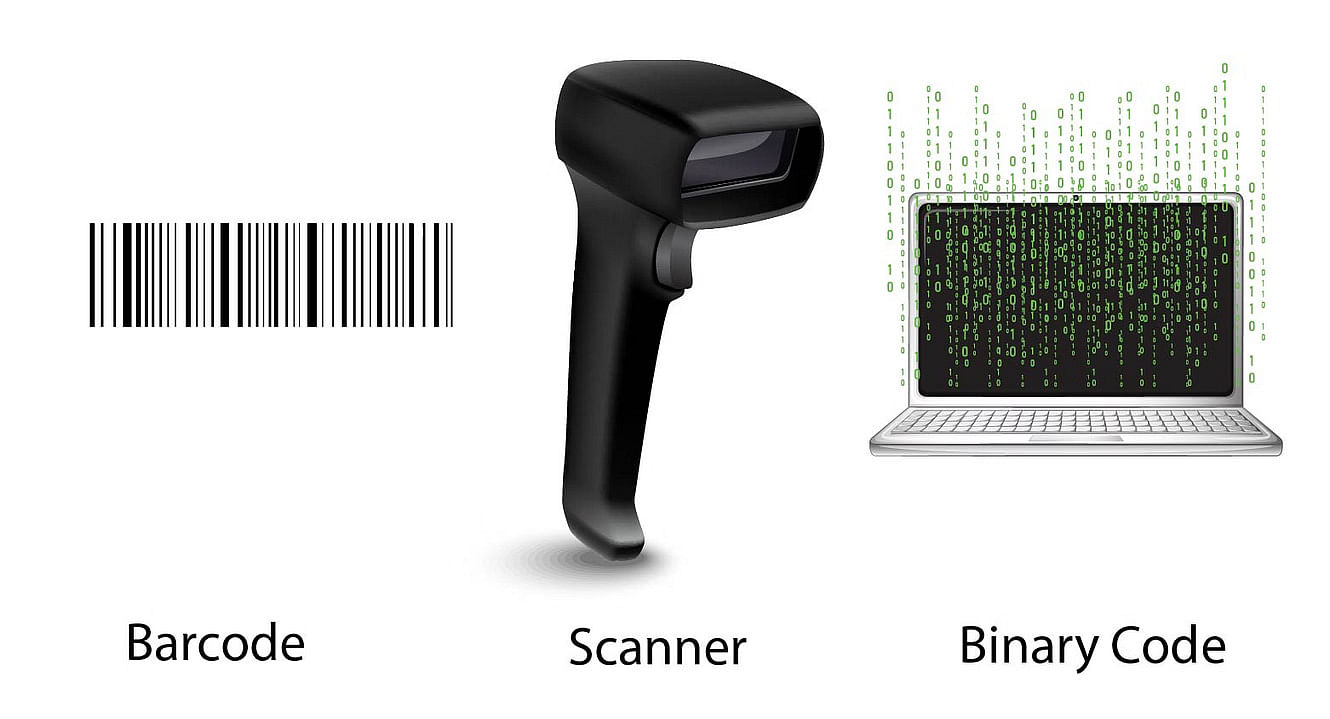

Barcode based inventory management system uses barcodes to track and manage inventory. A barcode is a digital code that can be read by computers and contains details about the product it is attached to. When scanned, the barcode is decoded, and its information is retrieved, allowing accurate barcoding for inventory management and tracking.

What Information Can a Barcode Contan?

A barcode can contain various types of information, such as product information, serial numbers, lot numbers, and location information. With the right software and hardware, barcodes can be used to track inventory in real-time, providing valuable insights into inventory levels, product movement, and more.

Which Types of Barcodes Are Available?

There are two types of barcodes available:

1) 1D

2) 2D

1D barcodes, also known as linear barcodes, are the most common type of barcode. They consist of a series of lines and spaces of varying widths that represent the encoded information. Examples of 1D barcodes include UPC, EAN, and Code 128.

2D barcodes, on the other hand, are more advanced and can store more information than 1D barcodes. They consist of squares, dots, and other geometric patterns representing encoded information. Examples of 2D barcodes include QR codes, a Data matrix, and PDF417.

How Does an Inventory System With Barcodes Operate?

The information gathered during picking is simply linked to your inventory management system by barcodes.

The picker and your inventory management system are thus both informed when the barcode is read that the right item has been chosen. Your real-time inventory tracking will now include the updated amount. Incorporating the updated amount into your real-time inventory tracking. Hence, it simplifies the work of your pickers and provides you with a precise real-time live inventory count.

Case Study: Barcode Based Inventory Solution for Ecommerce Store

Silent Infotech developed a barcode-based solution for a Shopify store integrated with Odoo ERP, which streamlined warehouse management and order fulfillment processes. The solution enabled real-time tracking of inventory levels and movements, automated order fulfillment, and increased efficiency and customer satisfaction.

Ways to Utilize Barcode-Based WMS Systems In Warehouse

Barcode inventory systems can be used in a variety of ways to improve warehouse efficiency. Here are a few examples:

Inventory Tracking

Barcode-based WMS systems allow for real-time inventory tracking, providing valuable insights into inventory levels, product movement, and more. This information can be used to make informed decisions about inventory management, reducing the risk of stockouts and overstocking.

Pick and Pack Operations:

Barcode-based WMS systems can be used to streamline pick and pack operations. Scanning barcodes at each stage of the process ensures that the correct product is being picked, reducing the risk of errors and improving efficiency.

Shipping and Receiving:

Barcode-based WMS systems can be used to track shipments as they move in and out of the warehouse. Scanning barcodes at each stage of the process ensures that the correct product is being shipped or received, reducing the risk of errors, and improving efficiency.

Quality Control:

A barcode warehouse management system can be used to track product quality. Scanning barcodes at each stage of the process ensures that any defects or issues are identified and addressed before the product is shipped to the customer.

How To Configure An Inventory System With Barcodes

Configuring an inventory system with barcodes can be a complex process, but with the right tools and expertise, it can be done efficiently. Here are the steps involved in configuring an inventory system with barcodes:

Choose the Right Barcode Format

Before configuring an inventory system with barcodes, you need to choose the right barcode format that fits your business needs. Consider factors like the size of your inventory, the number of products you need to track, and your existing infrastructure.

Barcode Printing

Once you have chosen the right barcode format, you need to print the barcode labels. This can be done using a label printer or by outsourcing the printing to a third-party provider.

Install barcode scanners

Barcode scanners are the key to a successful barcode inventory system. You need to install handheld scanners, stationary scanners or both based on your business needs.

Barcode scanning and data entry

Once the barcode labels and scanners are in place, you need to scan the labels and enter the data into the inventory system.

Integrating with other systems

If you are using an ERP system, you need to integrate it with the barcode-based WMS system to ensure seamless data exchange between the systems.

Effective inventory management can help businesses grow by ensuring the availability of products, streamlining order fulfillment, reducing costs, and increasing customer satisfaction. Get useful tips while reading this blog.

Benefits of Barcode-Based WMS Systems

Barcode-based WMS systems offer several benefits to businesses. Here are a few of them:

Accurate Inventory Tracking:

Barcode inventory system allows accurate inventory tracking, providing valuable insights into inventory levels, product movement, and more. This information can be used to make informed decisions about inventory management, reducing the risk of stockouts and overstocking.

Increased Efficiency:

Barcode-based WMS systems help streamline operations and reduce errors. With barcode scanning, the time taken for data entry is reduced, reducing the risk of human errors, and increasing efficiency.

Improved Customer Satisfaction:

Barcode-based WMS systems help ensure that the right products are shipped to the right customers on time, reducing the risk of shipping errors and improving customer satisfaction.

Cost Savings:

Barcode-based WMS systems can help reduce costs by optimizing inventory levels, reducing the risk of overstocking or stockouts, and streamlining operations.

Conclusion

A Barcode system for inventory management is an excellent way to improve inventory management and increase efficiency in your warehouse. By using barcodes to track inventory and manage stock levels, businesses can reduce errors, optimize inventory levels, and improve customer satisfaction. When choosing a barcode-based WMS solution, it is essential to consider factors like the type of barcode, hardware requirements, and software integration. With the right tools and expertise, configuring an inventory system with barcodes can be done efficiently, offering several benefits to businesses. Whether you are a small business or a large enterprise, setting up barcode inventory systems are a valuable investment that can help you achieve greater efficiency and profitability in your warehouse.